传统的DCS存在故障风险,并缺乏本地支持。我们决定迁移到PlantPAx,我们需要一家在精细化工行业拥有批量处理经验的罗克韦尔自动化系统集成商为我们提供帮助。

一家为造纸、水处理、皮革和各种特殊化工行业提供化学品的世界知名精细化学品生产企业准备更换其陈旧的DCS,LSI倾听了客户的意见,并开始改变客户的生产控制,为未来做好准备。

客户需求

客户使用的是过时的横河分布式控制系统(DCS),而且没有本地支持。作为一家高危险性化学品的制造商,他们深知其过程控制存在操作和安全风险、维护挑战以及意外停机的可能性,所有这些问题都不容忽视。他们的目标不仅是可靠、稳健、安全,而且是支持他们数字化转型目标的DCS平台。

在当地经销商Agilix Solutions的帮助下,客户选择了罗克韦尔自动化的PlantPAx DCS,并计划独立实施该项目。然而他们很快意识到,所需的时间和内部资源将大大延迟迁移的完成。LSI因此得到了一个绝佳的机会,与罗克韦尔的Encompass合作伙伴合作,提供一个全面的解决方案,满足客户的需求,并与他们的发展计划保持一致。

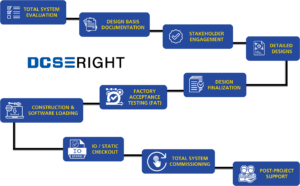

DCS≡RIGHT解决方案

LSI采用了DCS≡RIGHT方法,这是一个经过验证的流程,可以简化从传统控制系统到现代DCS的迁移过程。通过使用这种系统化的方法,我们能够最大限度地减少停机时间和风险,保持良好的沟通以消除意外和代价高昂的错误,并确保项目在预算范围内如期完成。

Total System Evaluation

During this discovery stage, LSI listened to the client’s needs and developed the vision for the new DCS. LSI then performed a thorough audit of the current control system to:

- Document existing control system architecture and identify risk points.

- Determine ways to maximize operations and reliability

- Explore opportunities for incorporating new technology and optimizing the system

- Determine how to mitigate downtime and maintain production continuity.

Several risks and challenges were identified during the audit:

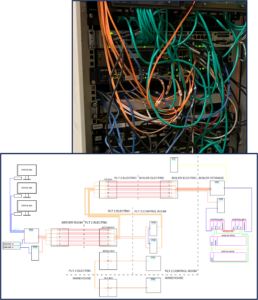

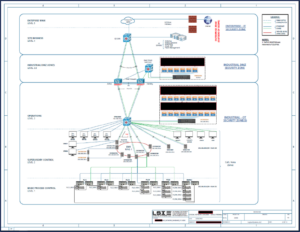

Architecture Issues

- Flat network architecture without any segmentation – no network management

- Plant was experiencing unexplainable controls network issues

Lack of Support for Legacy Yokogawa DCS

- No local technical support

- Limited integrator / 3rd Party Support

- No local distributor presence

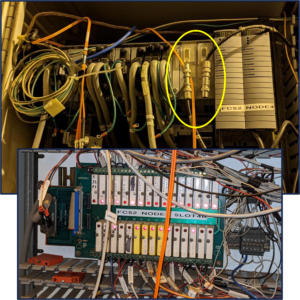

Failing DCS Hardware

- Coaxial-based communication backbone was failing and difficult to troubleshoot.

- Old I/O Modules failing, difficult to get replacements.

- “Abandoned” failed points on cards.

Tribal Knowledge

Business Risk due to reliance on tribal knowledge

Business Risk due to reliance on tribal knowledge- No electrical drawings, no I/O drawings, no motor control drawings

- No tag naming standard

- No documented control narratives / functional specs

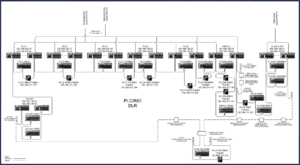

Lack of DCS Segmentation

Existing Yokogawa DCS had three controllers

Existing Yokogawa DCS had three controllers- No process segmentation for controllers

- I/O was landed to whatever controller was closest

- Resulted in a system where nothing can be taken down for maintenance.

- Any failure could bring the entire plant down.

Tedious Automation

- Changes to automation strategies were difficult to make

- Modular code did not exist in the legacy DCS

- No true “Batch” program – only a sequence table

- A lot of manual work was required to make programming changes

Knowing the capabilities of the PlantPAx system, LSI identified many opportunities for improvement during the audit:

- Digital transformation enablement:

- Set up for future MES integration to ERP system

- Set up for future Maintenance System integration for Predictive or Condition Condition-based maintenance

- Automated Batch Reporting will allow for elimination of paper batch sheets

- Set up for future automatic batch creation and recipe management from ERP

- Better tools for Process Improvement

- FT Historian allows for insights and improvements

- Modular Programming

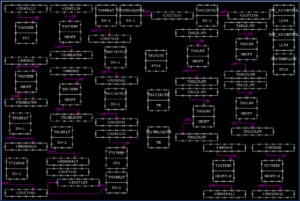

ISA -88 programming implemented -CM’s, EM’s, Phases

ISA -88 programming implemented -CM’s, EM’s, Phases- Batch flexibility of low code / no code. Process Engineers can maintain without specific Controls Engineer help.

Design Basis Documentation

Using what we learned during system evaluation, LSI formed a dedicated team and produced documentation that provided a high-level implementation plan for executing the DCS migration correctly.

- Developed the overall project Scope, Schedule, and Budget.

- We evaluated and determined the specific technologies to be used, engaging Rockwell Encompass partners.

- We created User Requirement Specification documents.

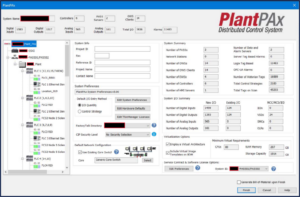

The PlantPAx System Estimator (PSE) was used to develop and size the system.

The PlantPAx System Estimator (PSE) was used to develop and size the system.- Design basis included:

Stakeholder Engagement

Stakeholder engagement is a key part of any successful DCS migration project. It begins with spending time with the operations crew (maintenance technicians, plant operators, etc.). We listened to the unique issues they experienced, documented their processes, and recorded the system’s functional requirements.

We also created and field-verified the drawings of the legacy equipment to ensure that plant details were accurate and up-to-date. Client stakeholders were engaged early and often, which cultivated a strong sense of ownership in the solution. This engagement extended to various roles within the organization including:

We also created and field-verified the drawings of the legacy equipment to ensure that plant details were accurate and up-to-date. Client stakeholders were engaged early and often, which cultivated a strong sense of ownership in the solution. This engagement extended to various roles within the organization including:

- Process Engineers – Input on functionality

- Operators – HMI look/feel, customization requests

- E&I / Maintenance – Design for reliability, standard parts

- Operations Scheduling – Downtime and commissioning plans

The bottom line is that we prioritize the customer because it’s critical to do what makes sense for the people running the system, not what makes sense for the controls engineer.

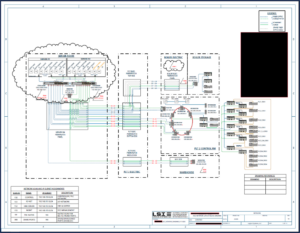

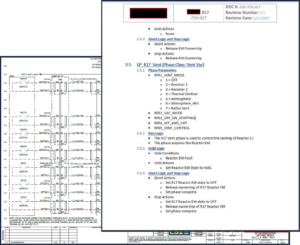

Detailed Designs

Once the pre-work was completed and the customer was on board, we began producing plans for the new system. This included hardware drawings and Functional Specification Documents for the software configuration. As we worked through and developed the design, we checked in with the customer regularly to avoid incorrect assumptions and allowed for input and tweaks along the way.

The detailed designs consisted of:

The detailed designs consisted of:

- Functional Specs – 34 documents

- Electrical Drawings – 310 drawings

- HMI Displays – 250 displays

- Software:

- Control Modules – 2,010

- Equipment Modules – 166

- Phases – 260

- Recipes – 35

Design Finalization

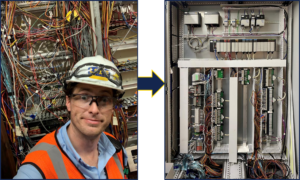

During this step, we fabricated 12 freestanding control panels, configured the software, developed process simulations and our testing plan, and internally tested the new DCS configuration. It’s important to note that we do a 100% internal test!

We also completed intermediate configuration reviews with the client along the way, ensuring we were on the same page – making sure there were no surprises at the Factory Acceptance Test.

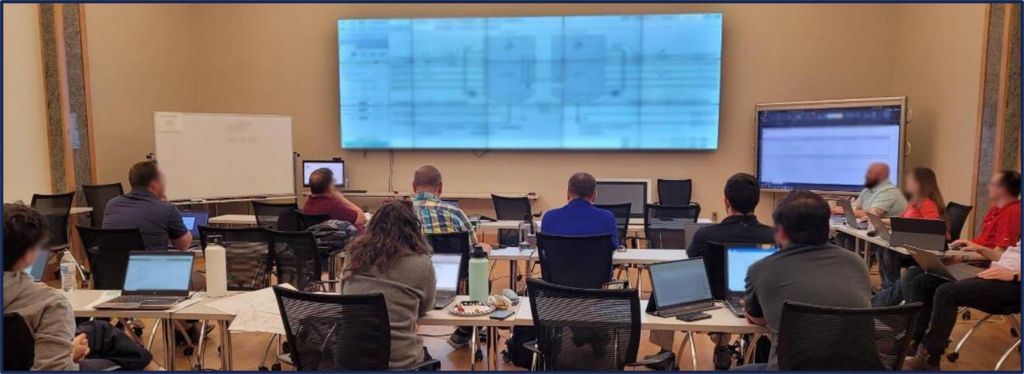

Factory Acceptance Testing (FAT)

We perform FAT at LSI’s Facilities to minimize distraction from the client team’s “day job”. Full simulations of the system are provided for client approval. Validation is a major component of DCS≡RIGHT because we believe this removes the white-knuckle ride from a start-up.

Highlights of the FAT:

- Engineers who have been working on the design are on hand to incorporate any changes in real time.

- 100% of the software was tested by LSI before the FAT

The documented Test Plan was approved by the client in advance.

The documented Test Plan was approved by the client in advance.- FATs were split by each process area.

- Six FATs were completed

- Software tested against Functional Spec as well as Tribal Knowledge of client resources.

- Check Sheet and Progress Tracking was used to ensure accuracy and timely completion.

- Engineers, Operators, and Maintenance invited to FAT maintain engagement and continuity.

Construction & Software Loading

Once the system had been fully tested and approved, we froze the configuration and executed our plan, replacing the old hardware and implementing the new software configuration.

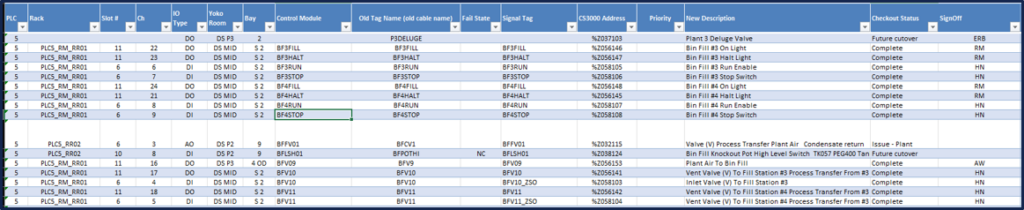

For this project, the construction and commissioning were split into five separate outages to minimize production impact. This required more coordination and providing temporary I/O mapping to facilitate the multi-stage commissioning.

For this project, the construction and commissioning were split into five separate outages to minimize production impact. This required more coordination and providing temporary I/O mapping to facilitate the multi-stage commissioning.

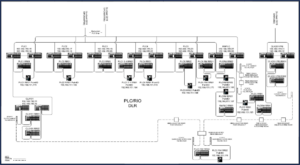

Construction took place in the following phases:

- Phase 1 – Controls Network Infrastructure

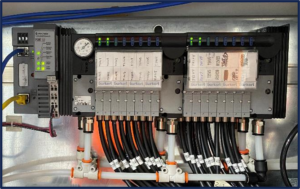

- Phase 2 – Ethernet Solenoid Manifolds – 800 I/O

- Phase 3 – 7 Unit Operations – 1,050 I/O

- Phase 4 – 4 Unit Operations – 850 I/O

- Phase 5 – 5 Unit Operations – 1150 I/O

IO / Static Checkout

After the new DCS was installed, we tested 100% of the field devices from the new control system, ensuring operational success and system reliability. Again, it’s the DCS≡RIGHT way.

Total System Commissioning

During commissioning, LSI was on-site with our clients to provide support and run the entire process. This project was commissioned in five phases to minimize production impact. Interim programming allowed the legacy DCS to work alongside the new PlantPAx DCS. 35 different batch recipes were commissioned – all with the significant challenge of having no ability to make a “test” batch. Our goal was to produce sellable product on the first batch. We are pleased to share that the first batch was a success and expensive scrap was avoided!

Post-Project Support

LSI provided 24/7 support until all the success criteria were fully met. We also provided ongoing support at the client’s request for tuning and minor updates.

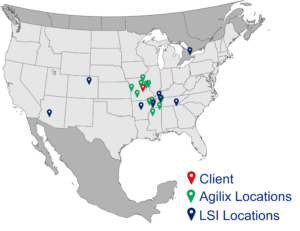

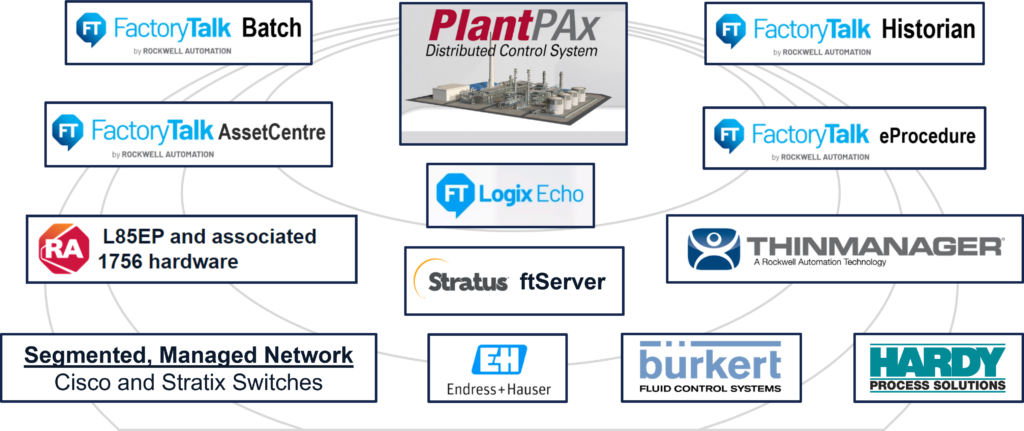

合作伙伴的全面解决方案

在DCS迁移中,合作伙伴关系的价值不容忽视,罗克韦尔自动化的Encompass合作伙伴在其成功中发挥了重要作用。

LSI与分销和Encompass合作伙伴合作一起提供了一个全面的解决方案:

- 我们用Burkert以太网/IP螺线管歧管取代了旧的120VAC硬连线螺线管

- 消除了硬连线I/O

- 原生集成到PlantPAx

- 我们提供了E+H仪器、Hardy称重秤和Powerflex VFDs

- 这些以太网/IP设备以前连接到单个L73 PLC,然后通过Modbus映射到DCS

- 迁移到PlantPAx允许本地集成并消除了Modbus映射

- Stratus ftServer

- 允许远程管理——由于客户端缺乏IT/OT资源,这一点很重要

- 完全冗余的虚拟化服务器

项目成果

一个安全的分段网络

- 按照普渡模型正确分段和保护网络

- IDMZ设计用于连接到企业网络

DCS 分段

- 控制器分段以与过程单元操作保持一致

- 能够关闭单个控制器并保持工厂其余部分运行

新硬件

- 全新DCS硬件

- 新型光纤和以太网控制网络

- 新的Stratix开关

- 新的ftServer和瘦客户端

- 新的L85EP处理器

- 新的1756 I/O

- 可提供长期支持和服务

本地支持

本地支持

- 多层本地支持

- 来自Agilix的本地分销商支持和零件供应

- 持续的LSI支持

- 庞大的罗克韦尔和合作伙伴支持网络

模块化自动化

模块化自动化

- PlantPAx 5.0

- 应用代码管理器(ACM)

- PAx对象

- 专为批量应用而设计的阶段

- FT批处理

数字化转型平台

安装了罗克韦尔自动化最先进的PlantPAx DCS后,客户可继续进行数字化转型。项目中使用的技术为他们的转型之旅助力:

有了PlantPAx,客户为未来做好了准备:

- 为未来MES集成到ERP系统(Plex)做好准备

- 为未来的维护系统集成做好准备,以实现预测性维护或基于状态的维护(Fiix CMMS)

- 设置仪器校准管理(FT AssetCentre或E+H FieldCare)

- 自动化批处理报告可消除纸质批处理表

- 为未来从ERP自动批处理创建和配方管理做好准备

更好的流程改进工具

- 可靠的历史数据可提供洞察力和改进意见(FT Historian)

LSI 倾听并交付

成功迁移PlantPAx后,客户使用FactoryTalk Batch简化了流程,确保了网络安全并对网络进行了分段,根据工艺单元的运行情况对控制器进行了分段,安装了新的DCS硬件,并可随时获得本地支持和持续支持。有了PlantPAx,客户就拥有了一个成熟的平台,可在未来将MES集成到ERP系统(Plex)、将维护系统集成到预测性维护或基于状态的维护(Fiix CMMS)、仪表校准管理(FT AssetCentre或E+H FieldCare)、自动批量报告以及更好的流程改进工具(FT Historian)。

您是否正在寻找一个能帮助您提高运营绩效的合作伙伴,以助您的公司迈向未来?让我们今天就开始对话——LSI倾听您的声音。